OVERVIEW

Heat exchangers: operating in Ammonia oxidation plants

- Perform an important role for heat recovery and steam production

- Operating fairly close to engineering design temperature limits (eg. Creep)

- Longevity & sustainable performance desired

- Time consuming to maintain / repair / replace

- Precious metals deposit on heat exchangers

- Other process materials can also deposit (eg. Debris)

- During operation thermal efficiency is progressively reduced with the following effects:

- Increased component & equipment temperatures locally and downstream

- Reduced steam production

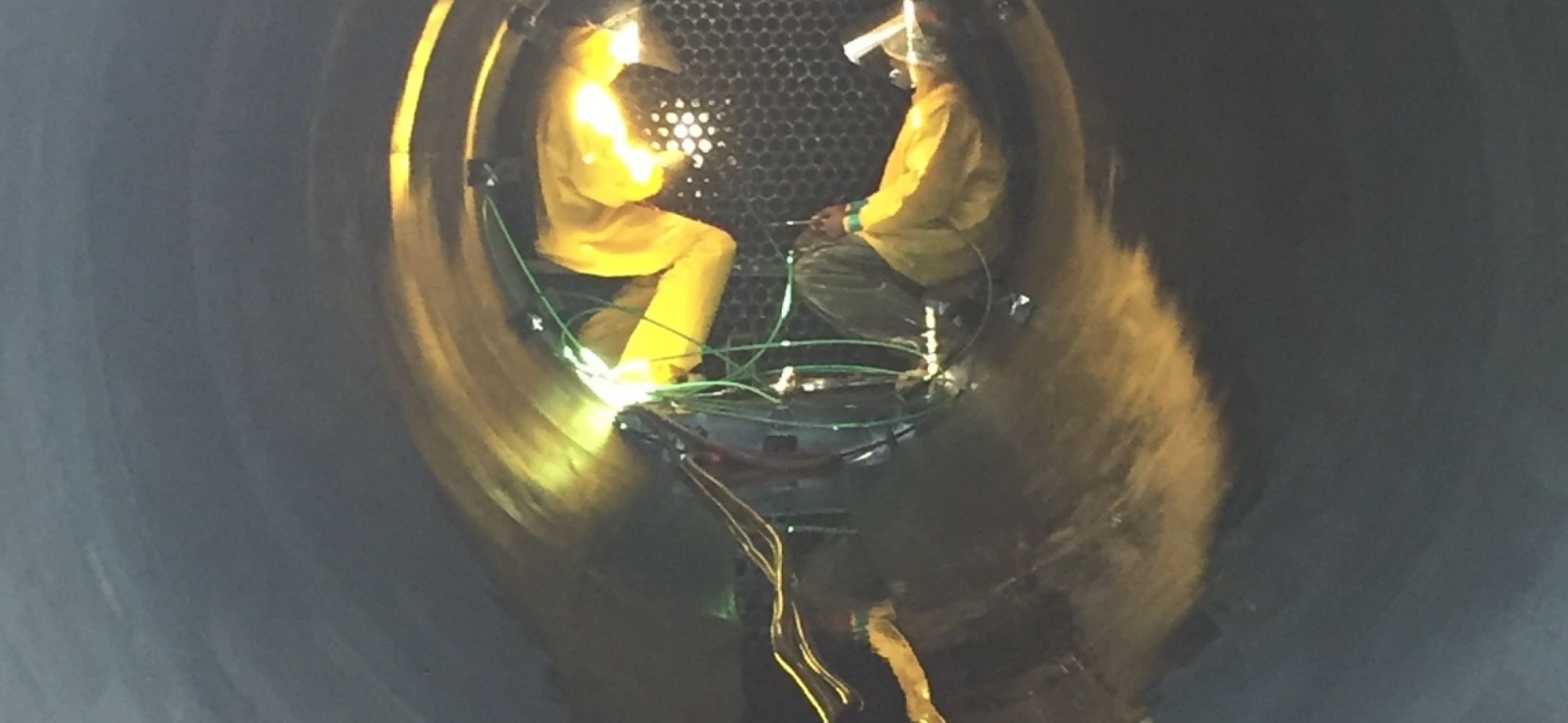

BDB Services (URSG)

Industrial Cleaning – Non-Destructive / Non-Acidic

- Safe, Effective & Environmentally Friendly cleaning methods

- The use of patent pending Non-Acidic cleaning technologies and high pressure washing solutions to remove robust surface deposits and maximise plant efficiencies.

- Non-acidic cleaning mitigates risk of damage to operational plant and equipment and is a much safer option than alternatives.

Industrial Cleaning – Destructive / Acidic

- Using a concentrated acidic solution to aggressively break surface deposits away from steel tubes / shells to maximise PGM recovery.

Industrial Cleaning – Recovery from other Vessels

- PGM’s can also collect in downstream vessels including storage tanks

- Safe working methodologies & risk assessments to assist plants

- Experienced team & ability to efficiently recover, filter, neutralise and prepare PGM bearing materials ready for shipment.

Precious Metal Recovery

- Collection, filtration & packaging of surface contamination resulting from the industrial clean.

- Packaged material may be shipped to a facility for refining & recovery of platinum group metals (PGMs).

- BDB (URSG) have refining facilities in the USA & Norway, offering clients a “one stop” option.

- URSG – Joplin Missouri www.unitedrecoveryservices.com

- K.A. Rasmussen – Norway www.ka-rasmussen.no